How To Make Money With a CNC Machine in 2023 (Guide)

If you want to earn $3,200 extra a month just by selling wooden signs made with a CNC machine then this article is for you. In most cases making money demands that you have some knowledge in different kinds of crafts or that you have a huge following on social media.

This is a skill that not many people know about but it is actually one of the most diverse skills you can have when it comes to making money. If you know how to CAD for a CNC machine you can basically make anything and with anything I mean products that people want to buy.

In this article we are writing about different items you can make and sell but also how to make money with a CNC machine and router. So if this is something you are good at and want to make money on you should definitely keep reading.

What Is a CNC Machine?

CNC stands for Computer Numerical Control, but for most people they are known as automated machines which are operated by computers executing work orders. These work orders are pre-programmed sequences of commands made by humans who designed different layouts for the CNC machine.

Today’s CNC machines understand what machining language G-code – which tells them exactly and precise measurements for production, feed rate, speed, location and coordination from those drawings. These machines are highly automated and are defined by using CAD software, therefore it is important to have knowledge in CAD to be able to run a CNC machine.

10 Different Types of CNC Machines

There are lots of different kinds of CNC machines and custom built machines for companies doing different tasks but in this article we are going to discuss some of 12 most common ones. All of these different CNC machines are great for making money and have the capacity to make different kinds of items that you can sell.

- Lathe CNC Machine

A CNC lathe machine is normally used to produce precise round shapes, an example could be legs for chairs and tables. Practically all kinds of wooden structures could be machined with this machine tool, depending on their needs in different industries.

- Plasma Cutting CNC Machine

An CNC plasma cutter is a machine that is designed to cut through hard materials like steel, aluminum and stainless steel with hot plasma that the CNC machine produces you can cut out any kind of shape making it a great tool for the steel industry.

- Drilling CNC Machine

A drilling machine is a rotating cutting tool to produce round holes in the material you put in it. It works in a similar way to a pillar drilling machine but compared to electric drilling machine this one is programmed with CAD and is operated from a computer.

- Milling CNC Machine

CNC milling is similar to other drilling machines with its rotating tools but the cutting tool is mounted on a rotating spindle so it can move sideways. There also is a rotation in the milling table or in your milling machine, it is possible to work in many different angles. With this tool you can make more complex shapes and work in angles other machines can’t.

- Grinding CNC Machine

One cool machine is a CNC grinder and it is an automatically operated grinding machine and the way this machine works is that it is in charge of refining the surface of a product you made. The machine works on metal and is slowly grinding away on any kind of surface that you want to finalize similar to a grinding wheel.

- CNC Wood Router

The CNC wood Router is a tool that creates objects from different kinds of wood. This machine shares some characteristics with a traditional milling machine but is designed to work on wood rather than metal. Many people make these CNC wood routers to make signs, different plaques, games, small cutting boards, and flags.

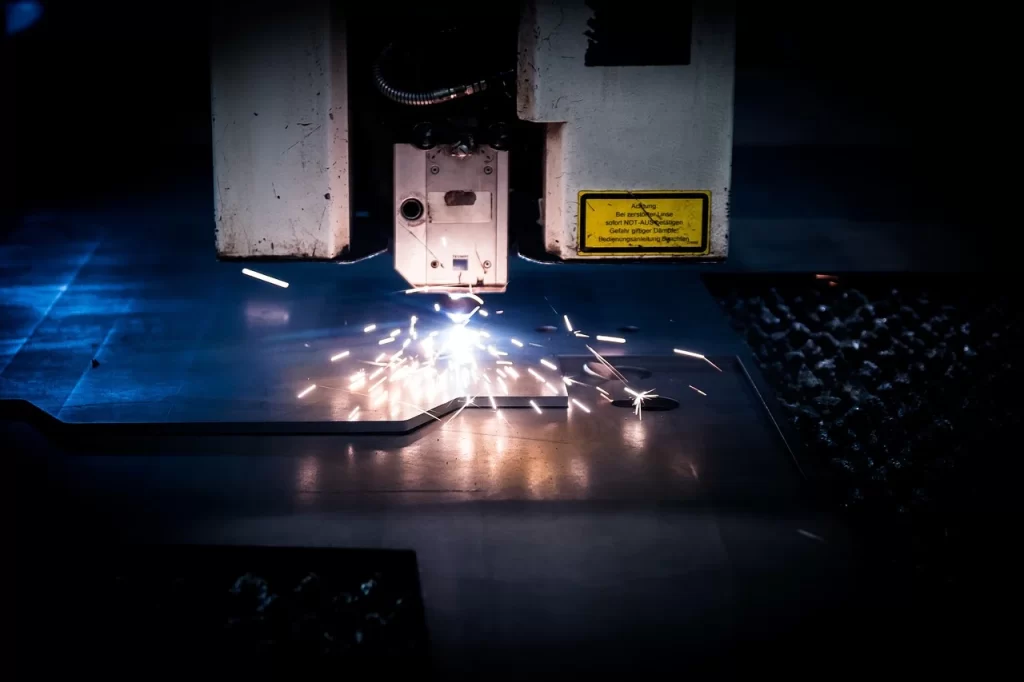

- Laser Cutting CNC Machine

A CNC laser cutter is a very diverse tool that uses a focused, high-powered laser beam to mark different materials, to cut, or engrave a material to form custom shapes from a drawing. The unique way it operates is that it is highly accurate, especially when cutting shapes and small holes.

- Router CNC Machine

The Word Router comes from “rout” meaning to hollow out or carve out.

CNC routers are machines that are used for cutting many types of materials such as wood, plastic, aluminum, and hard foam.

- Electric Discharge CNC Machine

An Electrical discharge machining uses electrical energy, it erodes material and because that machine generates a series of high-frequency sparks between object and electrode.

- CNC Machine With Automatic Tool Changes

A CNC machine with ATC (automatic tool changer) can be built in on most of the CNC machines mentioned above and it is a tool that improves production. ATC changes tools rapidly making the machines more diverse and are able to work on different tasks more efficiently.

Creative Ways To Use a CNC Machine

Depending on what machine you have and what kind of CNC project you want to make money on you have to check what your machine can do and what kind of CNC projects you want to take on. Here is a list of different creative items you could make with your CNC machine.

- Roman Clock

This is a unique clock made by ZenziWerken and is a stunning clock with roman numbers.

(link here)

- Kinetic Sculpture

If you like unique designs you definitely have to look into different kinds of kinetic sculptures people have done with their CNC machines. (link here)

- Parametric Desk Cubby

This is a parametric object that really displays that machine’s capabilities and what a X-carver can do. Check out the unique storage solution. (link here)

- 3D Structure Trivet

This is a unique 3D structure made with a CNC machine and this particular item is made for holding hot pots and pans off the table. (link here)

- Dodecahedron Lamp

With its unique cube design this lamp sure is unique and shows of the artist work. (link here)

- Space Frame Stool

This stool looks like it has been taken out from a spaceship and really holds a unique design. It looks like it is made out of metal but in the same time you know it is wood (link here)

When you browse through these objects I really hope this gave you some inspiration on what creative things you could do with your CNC machine and if possible great ideas for making something unique for you or your customers.

How to Make Money With a CNC Machine

With all different machines listed in this article there must be ways to make money with each CNC machine right? Yes, making money with CNC machines is probably even easier than handcrafting items to sell, but it requires that you know what you are doing and you know how to operate the machine.

First we have to briefly talk about what it cost to acquire that exact machine, and how long it takes to make the design, to buy different tools needed for the machine and byt materials you are going to work with. But this is not a bad thing, people know that CNC machines are expensive and that you need certain skills to operate them.

So you could charge a higher price compared to what a person doing a side hustle would do. But you still need to make products that people want and they might be hard for regular craftsmen to do.

How Much Money Can You Make?

In this example about how to make money with a CNC machine, we are going to be calculating on a project making a wooden sign.

We are going to create a wooden sign with the size 16” x 19” with a wood that is ¾ inches thick.

I am calculating with a machine that costs around $3,200 and that the machine will be used for around 260 hours each year.

So if we split the buying price with x hours we get a price around $12.3 for one hour of work, but there is maintenance after a while so we will bring the hour cost up to $13.54, that is approx 9%. But we also have some tools like drills and other small parts that we are going to use that will break after a time so we round up to $14 just to be safe.

Now we need electricity and material (wood) and the price for that is $30.

But there is more, we want money for the time we put in right?

We want to get a hourly salary of $30, that brings our total cost up to $14 + $30 + $30 = $74.

So if that sign sells for $74 we break even?

Not quite actually, you want money you put into your design as well, most people calculate this cost as something you want to charge your customer. But I never do because when I decide to make a product to sell I design it so I can sell a number between 10-100. And because this is a side hustle business you really don’t need a salary either, so you could make profit over $44.

But making products too cheap is not beneficial for the market so always look at what other CNC creators price their products and try to match theirs. The typical margin is around 10-30% so find an object that you know you can make to keep high margins but still be competitive to the market and other sellers.

In this calculation you will get all money back for the CNC machine in a little more than 100 hours and this is the best way on how to make money with a CNC machine and how you earn money with your CNC machine!

Things To Make and Sell

If you have trouble finding ideas on what to make and sell here is a good list of different items that are popular on different platforms. These have different learning curves so some are beginner friendly while others are more for the advanced users.

Home Products

Bookends

Candle holders

Furniture

Picture frames

Shelving

Wall Art

Kitchen & BBQ Tools

Coasters

Cutting Boards

Kitchen Wall decals

Wooden Bowls

Wooden Serving trays

Wooden Serving Utensils

Wood Bottle Openers

Wood Spoon

Office Supplies

Charging Docks

Craft Supply boxes

Desk Organizers

Paper Holders

Pencil Holders

Custom Signs

Changeable Letter Signs

Name Signs

Rustic Wood Signs for Outdoors

Wooden Wall Frames

Toys and games

Board Games

Children’s Letter Blocks

Children Toys

Dollhouses and Accessories

Puzzles

Other CNC products to sell

Birdhouses

DIY Project Kits

Jewelry

Tree Ornaments

Where To Sell Your Products

Most people only rely on one platform to sell their products but what they should do is to diversify and look into more than one platform to make sales. Here are 9 different places where you can sell your products.

- Etsy is the number one place to sell crafts.

- Facebook Marketplace is also a great place to sell stuff locally and without fees.

- Yard Sales, perfect to get to know the locals.

- Ebay, a great site like Etsy.

- Social media, your friends might want a CNC carved product.

- Your own website, get a homepage and sell your products without fees.

- Farmers markets, great to reach out to potential customers.

- Craft fairs and festivals, people love unique things.

- Shops, ask your local shop if they can sell your products for a small part of the profit.

All of these options are great ways to gain customers and expand your business rapidly.

Is Buying a CNC Machine Worth it?

The first thing you should think about is if this is something you think you could learn because a CNC machine is not a easy money making tool to learn. A CNC machine is not something that you just can buy and it can stand there pushing out items and products for you to sell, it needs you to put hours into designing, programming and operating to be able to make something that you can sell.

These machines are really expensive and most machines go for $2,000 at minimum and they can go as high as $20,000 or higher. So buying something that expensive can’t be done in a heartbeat you know, do your research, start taking lessons on youtube, get the design tool and start making different shapes. One thing you could do is to make a design and take it to your local CNC workshop and see if they can make the product for you.

But don’t let this stop your dreams, if this really is something you want to do you should definitely go for it!

CNC Machine vs CNC Router: What’s The Difference?

In most cases a CNC machine is not a specific product, it is more a collector name for some of the CNC machines out there on the market, and most CNC machine allows for different angled 3D cutting tasks like using lathe tools and other cutting tools. So with the right set of tools and input from start, the machine can operate in different levels and make products that are worked in a 3D dimensional way.

CNC routers on other hand is an advanced type of tooling method where they use tools to cut various shapes into various materials for different purposes. The capacity of a CNC routers offers more effective cuts than manual controllers routers. This gives a great spike in productivity and efficiency.

Are There Alternatives to CNC Machines and Routers?

Not really, CNC machines are the future of regular machines like wood lathes, milling machines and cutters. If you were to switch to one of those machines you would take a step back in effectiveness and productivity.

But there are certain times when a manually operated machine is better and that usually is when there are complex forms to make or size is too great for the machine. So if you have a bigger CNC machine the higher cost you get and some companies can’t afford such a huge cost.

Pros and Cons

Pros:

- Produce high-precision parts with high accuracy and repeatability, which can be highly valuable to various industries.

- Great for automate the production process, which can save time and labor costs, and can increase productivity and efficiency.

- CNC machines can produce a wide range of products, from simple parts to complex assemblies, which can allow you to serve a diverse range of customers and markets.

- Highly versatile to produce a wide range of materials, including metals, plastics, and composites.

- Custom and personalized products, which can be valuable to customers who require unique or specialized products.

Cons:

- Expensive to purchase and maintain, and may require specialized skills and knowledge to operate and program.

- Require significant space and infrastructure, and may require additional equipment and tools to produce high-quality products.

- Produce waste and emissions, which can impact the environment and may require special disposal or management.

- Subject to regulations and standards, which can vary depending on the industry and the product being produced.

- Obsolescence and technological change, and may require frequent updates and upgrades to remain competitive and effective.

Frequently Asked Questions (FAQs)

Is a CNC Machine a Good Investment?

Yes, if you sell your products with a profit of 10-30% and your machine costs around $3,000 you could get the money back in around 100 hours and after that most money is profit.

What Can I Make and Sell With a CNC Machine?

Most popular things to make are Bookends, Candle holders, Furniture and Picture frames.

Can You Make a Living With a CNC Router?

CNC machinists make around $40,000 a year charging about $18 to $25 an hour. If you own the machine you can triple that amount.

Can You Make Money With a CNC Machine?

If you have a CNC machine for $3,000, you buy wood for $30 and some random equipment you can make a profit of $20-30 each hour.

How do I Sell CNC Products?

Most people sell their products on Etsy or Amazon but there are more places like Facebook, Instagram, Ebay and Shopify.

Conclusion

In this article we discussed how to make money with a CNC machine but also different options on how to start your CNC business. As mentioned in the text earlier this is a really great way to make money and if you want to buy or own a machine like this there is so much money to be made. There is also the great advantage to make things for yourself and gifts to your loved ones.

Once you start making money and have a small budget you can start buying drawings from people in Asia for a cheap price to make your profit even higher.

Related:

- How To Make Money With a Wood Lathe

- 73 Most Profitable Things To Rent Out in 2022 (Complete Guide)

- The Best Scrap Metal Items To Make Profit On in 2022 (Complete Guide)

- How Much Money Can You Make Mowing Lawns In 2022 (Complete Guide)

- What Equipment Can I Buy To Make Money? [29 Best Tools]

- How To Make Money With Abandoned Houses (Complete Guide)