How To Make Money With A Metal Lathe in 2023 (Complete Guide)

If you’re looking for ways to supplement your income, learning “How To Make Money With A Metal Lathe” can be a game-changer. By utilizing this tool, you can create parts and components from metal pieces and transform your creativity into a lucrative business. Regardless of whether you’re a novice or an expert, a metal lathe can offer a versatile and profitable means of income.

With patience and the right resources, you can easily turn your hobby into a profitable venture. In this article, we’ll share tips and knowledge to help you get started on your journey of making money with a metal lathe.

So how to make money with a metal lathe and how much can you make with your metal lathe?

Short Answer: Around $500 per month from your metal lathe side hustle.

But to be able to earn that kind of money you need to know how to do it. In this step-by-step guide I will explain everything you need to know to make money with your metal lathe!

What Is a Metal Lathe?

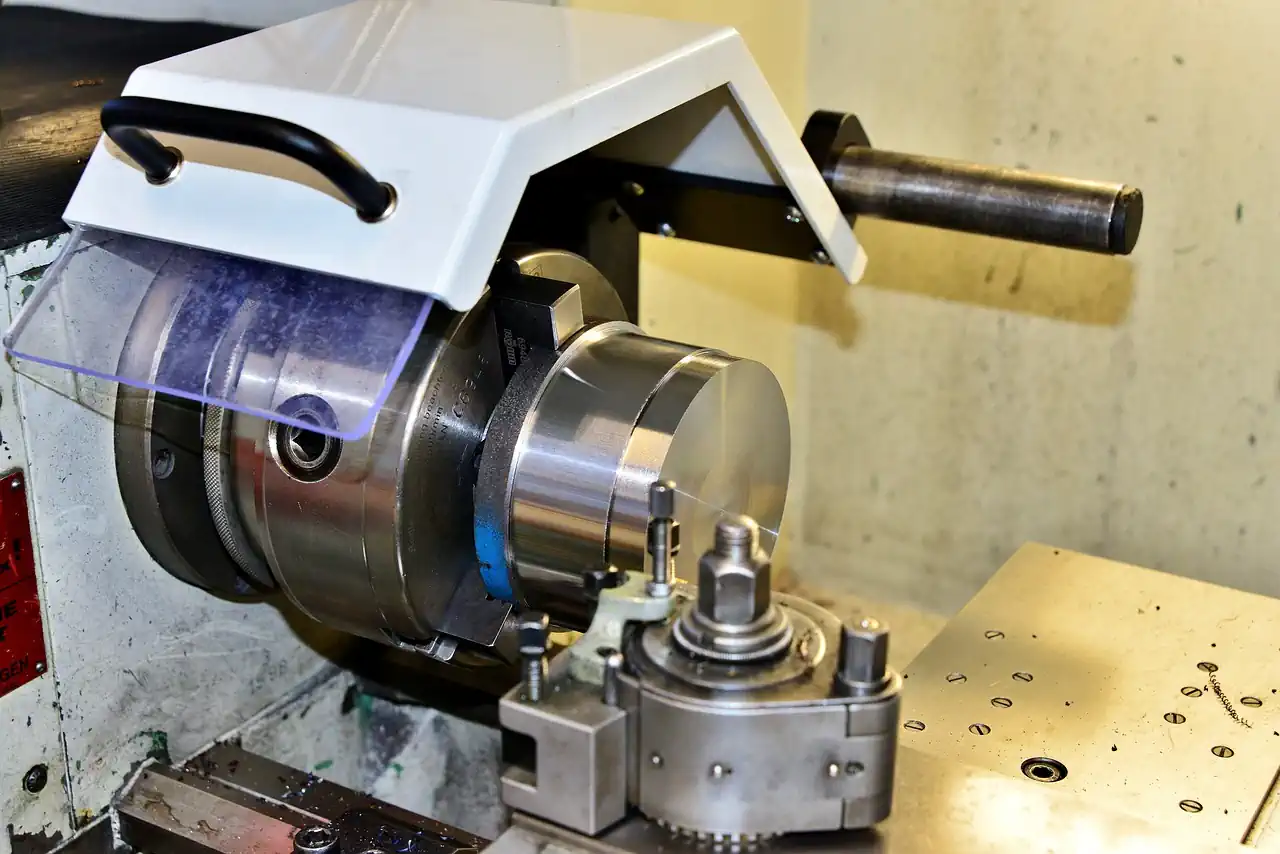

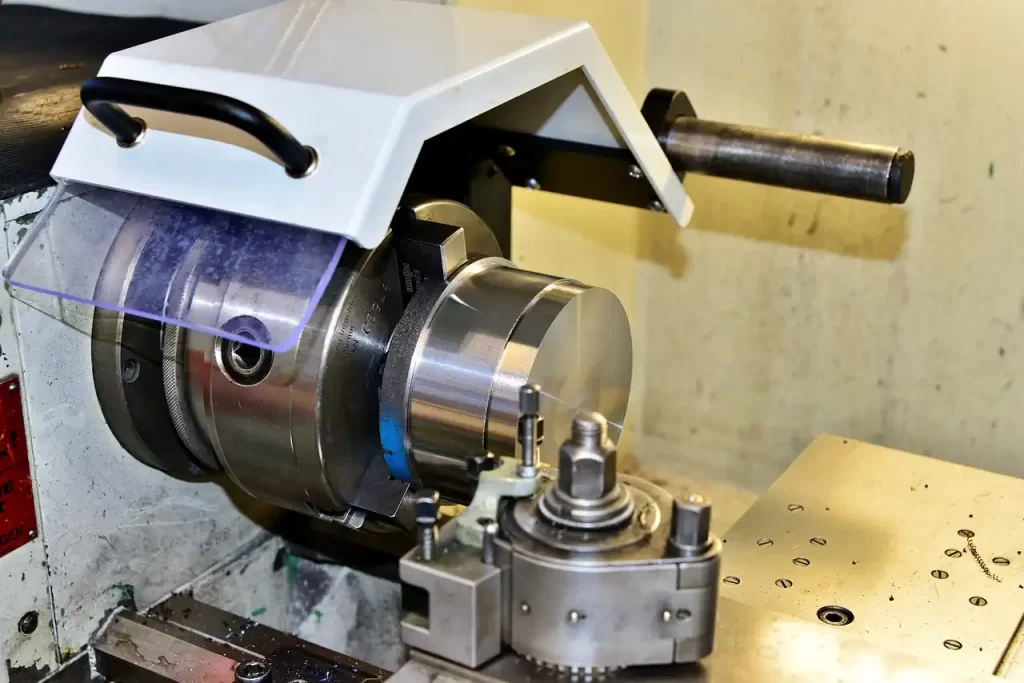

A metal lathe is a machine metal cutting tool that is used to shape metal pieces in a variaty of different metals suchs as iron, steel, copper, bronze, brass, aluminium and more.. It is commonly used to produce precision parts, such as screws, shafts, and bolts, by rotating the workpiece on a spindle and using cutting tools to remove material. A lathe can also be used to create other complex shapes, such as curved surfaces and tapers. It is a versatile tool that is used in many different industries, including automotive, aerospace, and medical device manufacturing.

Guide: How To Make Money With a CNC Machine in 2022 (Guide)

Creative Ways To Use a Metal Lathe

When you own a metal lathe it might be hard to come up with different ideas for what you want to create. But dont worry I got you covered on that subject aswell, here is a list with different kind of products you can make:

- Custom jewelry – Create unique and intricate jewelry pieces. By carefully shaping and polishing metal, you can create rings, pendants, and other pieces of jewelry with a high level of precision and detail.

- Creating sculptures – Create sculptures by shaping metal into the desired form and I know this can be a challenging but a rewarding process, as a lathe allows for a high degree of control and precision when shaping the metal.

- Making musical instruments – Musicians use lathes to create their own custom musical instruments and this typically involve shaping different bodies of the instrument, as well as strings, bridges, and other components.

- Custom car parts – If you are into automotive customization, a metal lathe can be a useful tool for creating custom car parts such as automotive customization parts or for example, you could create custom wheels, spoilers, or other exterior components.

- Making home decor – Create beautiful and unique pieces of home decor like a cool lamp but it could also nclude items like candle holders, vases, and other decorative items.

How to Make Money With a Metal Lathe

So you decided that you want to leave the life of working for someone else and that you want to learn how to make money with a metal lathe. This might start out as a side hustle or a way to get some extra cash but with a right dedication this can grow to something bigger if you want and are ready for it. That is why I guess you want to read everything you can to learn how to make most out of your metal lathe to make the most cash you possibly can!

Basic Skills and Techniques Required To Operate a Metal Lathe

Learning how to make money with a metal lathe includes operating the metal lathe, it may seem intimidating at first, but with practice and patience, it can become a satisfying and profitable skill. Here are some of the basic skills and techniques required to operate a metal lathe:

- Understanding the lathe parts: Before operating the lathe, it’s important to understand the different components and their functions. This includes the bed, headstock, tailstock, tool rest, and cutting tools.

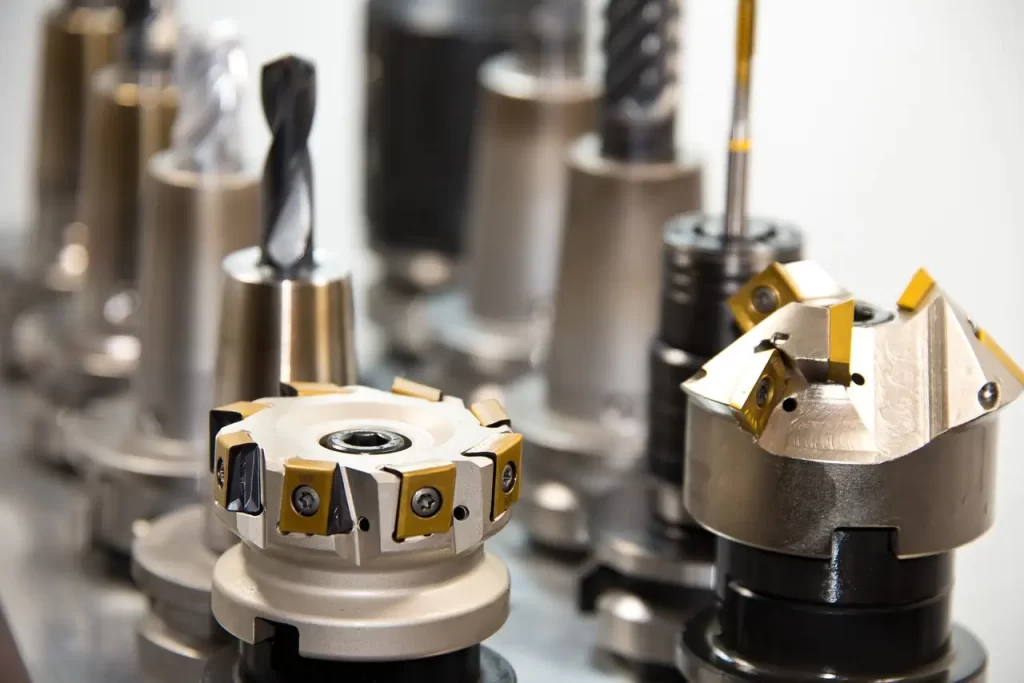

- Selecting the appropriate cutting tool: Choosing the right cutting tool is crucial to the success of the project. Factors to consider include the material being worked on, the desired finish, and the cutting speed.

- Setting up the workpiece: Once the cutting tool has been selected, it’s time to set up the workpiece. This involves securing the material in the chuck and aligning it with the tailstock center.

- Adjusting the cutting speed: The cutting speed depends on the material being worked on, the type of cutting tool, and the desired finish. A slower cutting speed is generally used for harder materials, while faster speeds are used for softer materials.

- Operating the lathe: Once the workpiece is secured and the cutting tool is adjusted, it’s time to turn on the lathe and begin cutting. The cutting tool should be moved along the workpiece at a steady pace, with light pressure applied.

- Finishing the workpiece: Once the cutting is complete, it’s important to finish the workpiece with sandpaper, polishing tools, or other finishing techniques as necessary.

These are just a few of the basic skills and techniques required to operate a metal lathe. With practice and experience, you’ll be able to create a wide range of parts and components from metal pieces, and turn your hobby into a profitable business.

Identify Profitable Niches and Markets For Metal Lathe Products

If you’re interested in making money with a metal lathe, it’s important to identify profitable niches and markets for your products. Here are some steps you can take to identify these areas:

- Research your competitors: Look at what other metal lathe businesses are offering and where they are finding success. This will give you an idea of what niches and markets are already being served, and where there may be gaps in the market.

- Identify trends: Keep an eye on trends in industries such as automotive, aerospace, and manufacturing, as well as emerging technologies and products. These may present opportunities for unique metal lathe products that fill a specific need.

- Leverage your expertise: If you have expertise in a particular industry or material, such as machining parts for motorcycles or working with exotic metals, you can use this knowledge to create specialized products that cater to those markets.

- Consider custom orders: Many businesses and individuals need custom metal parts for specific projects. This presents an opportunity to create unique products and build relationships with customers.

- Look for underserved markets: Consider markets that may be underserved by current metal lathe businesses, such as artisanal crafts, furniture, or home decor. These markets may offer a unique opportunity to create in-demand, high-margin products.

By identifying profitable niches and markets for your metal lathe products, you can focus your efforts and resources on areas where you have the greatest chance of success. With the right strategies and business acumen, you can turn your metalworking hobby into a profitable venture.

The Different Types of Metal Lathes And Their Respective Features

Metal lathes come in different types and sizes, each designed for specific applications. Here’s an overview of the different types of metal lathes and their respective features:

- Benchtop lathe: Benchtop lathes are smaller, compact lathes designed for use in home workshops or small businesses. They are easy to use and often come with basic features for hobbyists and beginners.

- Engine lathe: Engine lathes are larger and more versatile, designed for machining large parts and components. They can be used for cutting threads, turning, facing, drilling, and more. They are ideal for businesses in the manufacturing, automotive, and aerospace industries.

- Turret lathe: Turret lathes are highly automated, designed for high-volume production of identical parts. They are capable of performing multiple operations without manual intervention, making them highly efficient.

- Toolroom lathe: Toolroom lathes are designed for precision machining and high-quality finishes. They are used in tool and die shops, prototype manufacturing, and other industries where high accuracy is critical.

- CNC lathe: CNC lathes are computer-controlled and offer highly accurate and efficient machining. They are used in a wide range of industries and applications, from automotive manufacturing to aerospace engineering.

- Swiss-style lathe: Swiss-style lathes are designed for small, intricate parts that require high precision. They are used in the medical device, electronics, and watchmaking industries.

Each type of metal lathe has its own unique features and benefits. When selecting a lathe for your business, it’s important to consider your specific needs, the types of materials you’ll be working with, and the level of precision and automation required. With the right lathe, you’ll be able to create high-quality parts and components with speed and efficiency.

How To Source Materials and Tools Required For Metal Lathe Work

If you’re looking to learn how to make money with a metal lathe, sourcing high-quality materials and tools is essential for producing high-quality products. Here are some steps you can take to source the materials and tools required for metal lathe work:

- Identify your specific needs: Before you start sourcing materials and tools, it’s important to identify your specific needs. Consider the types of materials and parts you will be working with, as well as the level of precision and quality required.

- Research suppliers: Research suppliers of metal materials and tools, both locally and online. Look for suppliers with a good reputation for quality and reliability, and read reviews and ratings from other customers.

- Compare prices: Once you’ve identified potential suppliers, compare prices for the materials and tools you need. Be sure to consider shipping costs, as these can add up quickly for heavy or bulky items.

- Build relationships: Building relationships with your suppliers can be valuable for securing better prices, getting access to new products, and receiving support when you need it. Consider attending trade shows or industry events to meet suppliers and learn about new products.

- Consider buying used: Buying used tools and equipment can be a cost-effective way to get started with metal lathe work. Look for used equipment in good condition, and be sure to inspect it carefully before making a purchase.

- Invest in quality: While it can be tempting to cut costs by purchasing lower-quality materials and tools, investing in high-quality equipment can pay off in the long run by producing better quality products and reducing downtime due to equipment failure.

By taking the time to research and source high-quality materials and tools, you’ll be better equipped to produce high-quality products with your metal lathe. With the right tools and materials, you’ll be able to create a profitable and successful business.

The Importance of Proper Safety Measures When Using a Metal Lathe

When using a metal lathe, proper safety measures are absolutely essential. This is because there is a high potential for serious injury if the equipment is not operated correctly. Loose clothing, jewelry or long hair can easily become caught in the lathe, resulting in serious injury or even death. In addition, metal lathes generate sparks and heat, which can pose a fire hazard if not properly managed. Exposure to harmful materials such as metal shavings, coolant fluids, and lubricants can cause respiratory problems, skin irritation, and other health issues. Finally, depending on your location and industry, there may be regulatory requirements for safety measures when using a metal lathe, and failing to comply with these regulations can result in fines and legal action.

To ensure proper safety when using a metal lathe, it is important to follow safety guidelines and procedures, such as wearing appropriate personal protective equipment, keeping the work area clean and organized, properly maintaining the equipment, and using fire-retardant materials. It is also essential to receive training on how to operate the metal lathe safely and to understand the potential hazards associated with metalworking. By taking these steps, you can create a safe and productive metalworking environment that will allow you to maximize your earning potential.

A Step-By-Step Guide on How To Create And Sell Metal Lathe Products

Learning how to make money with a metal lathe includes learning how to create and selling metal lathe products can be a rewarding and profitable venture. With the right approach and tools, you can turn your passion for metalworking into a successful business. This step-by-step guide will provide you with the knowledge and skills you need to create and sell high-quality metal lathe products in a profitable niche.

- Identify a profitable niche: Research the market to determine which metal lathe products are in high demand. Consider factors such as price, competition, and potential customer base to determine which niche is right for you.

- Source materials and tools: Identify the materials and tools you will need for your metal lathe products, such as raw materials, cutting tools, and measuring instruments. Purchase these items from a reliable supplier.

- Develop designs: Create designs for your metal lathe products using drafting software or by hand. Use your creativity and knowledge of the market to create unique and appealing designs.

- Set up your metal lathe: Set up your metal lathe according to the manufacturer’s instructions. Ensure that it is in good working order and that all safety measures are in place.

- Begin production: Start producing your metal lathe products using the designs you have created. Take care to follow all safety procedures and to produce high-quality products.

- Test and refine: Test your products to ensure that they meet your quality standards. Refine your production process as necessary to improve efficiency and quality.

- Market your products: Develop a marketing strategy to sell your metal lathe products. Consider setting up an online store, attending trade shows, or reaching out to potential customers directly.

- Manage your business: Manage your business operations, including finances, production, marketing, and customer service. Continuously monitor your operations and make adjustments as necessary to ensure profitability and growth.

By following these steps, you can create and sell high-quality metal lathe products that are in high demand in the market. With patience, hard work, and dedication, you can turn your metalworking hobby into a profitable business.

Guide: How To Make Money With a Wood Lathe

How Much Money Can You Make with a Metal Lathe?

So you are interested in turning your metalworking hobby into a profitable venture and by learning how to make money with a metal lathe that can become reality! By using this versatile tool, you can create a variety of parts and components from metal pieces and sell them for a profit. In this article, we’ll share some tips and ideas to help you get started on your journey of making money with a metal lathe.

Answer: As with any business venture, the amount of money you can make with a metal lathe as a side hustle will depend on a variety of factors, such as different types of products you make, demand for those products, prices you charge, amount of time and effort you put into your business. Generally, highly skilled lathe operators can make anywhere from $13-$32 per hour.

Let’s assume that you are charging a standard rate of $50 per hour, and that it takes you one hour to complete a job on the metal lathe. If you take on three jobs per day, with each job taking one hour to complete, you can make $150 per day from metal lathe work.

But you probably don’t have the time to do that many objects so let assume that you charge $50 per hour for each job, and you can take on 10 jobs per month, you would make $500 per month from your metal lathe side hustle.

Potential Earnings Calculation

So when you know how to make money with a metal lathe it is time to calculate how to earn money with your metal lathe. Usually it depend on a number of factors such as what type and size, type of work you do with and the market for your work.

Let’s say you have a metal lathe that is capable of producing precision parts for various industries, such as aerospace, automotive, or medical. You charge $50 per hour for your services, and you work 40 hours per week. If you work 50 weeks per year, you will earn a total of $100,000.

Here is the calculation:

Hourly rate for lathe services: $50

Hours worked per week: 40 hours

Weeks worked per year: 50 weeks

Weekly earnings: $50 x 40 hours = $2,000 a week!

Total earnings per year: $50 x 40 x 50 = $100,000 a year!

In this example, you would earn a total of $100,000 per year by using your metal lathe to produce precision parts for various industries. The amount of money you can earn with your metal lathe will vary depending on your individual circumstances and the market for your work.

Things To Make and Sell

There are many things that you can make and sell with a metal lathe, depending on your skills, interests, and the market demand. Here are a few ideas to get you started:

- Custom jewelry – Create unique and intricate jewelry pieces, such as rings, pendants, and earrings by shaping and polishing metal, you can create beautiful and high-quality jewelry that customers will be willing to pay for.

- Sculptures – By shaping metal into the desired form and making it unique this can be a challenging but rewarding process, and the finished sculptures can be sold to collectors and art enthusiasts.

- Musical instruments – Create their own custom musical instruments, such as guitars, drums, and wind instruments by carefully shaping the metal and adding all necessary components, you can create unique and high-quality instruments that musicians will be interested in purchasing.

- Custom car parts – A metal lathe can be a useful tool for creating custom car parts like wheels, spoilers, exhaust pipes, and other exterior components that can be used to enhance the look and performance of a vehicle.

- Home decor- Make beautiful and unique pieces of home decor, such as candle holders, vases, and decorative bowls by carefully shaping and finishing the metal, you can create items that will add a touch of elegance and sophistication to any home.

Where To Sell Your Metal Lathe Products

There are many different places where you can sell your metal lathe products, depending on what type of products you make and the target market you are trying to reach. Here are a few ideas to get you started:

- Online marketplaces – Marketplaces, such as Etsy, Amazon, and eBay, can be a great place to sell your metal lathe products and these platforms have a large audience of potential customers, and they make it easy to set up an online store and start selling your products.

- Your own website – Create your own website and sell your products directly to customers, but remember that his will require some upfront work to set up the website and establish an online presence, but it can be a good way to build your brand and create a more personalized shopping experience for your customers.

- Local craft fairs – Traditional or handmade items, local craft fairs can be a good place to sell your products and these events typically attract a lot of local customers who are interested in supporting small businesses and buying unique and handmade items.

- Specialty shops – If you are making specialized products, such as custom car parts or musical instruments, you may want to look into if you can sell your products through specialty shops that cater to those markets. This can be a good way to reach a targeted audience of customers who are looking for the specific products that you offer.

- Wholesale – If you are producing a large quantity of products, you may be able to sell your products wholesale to retailers who can then sell them to their own customers. This can be a good way to reach a larger audience and earn more cash!

How do I Sell My Products?

To sell your metal lathe products, you will need to follow these steps:

- Develop your skills with the lathe with like Youtube videos, online tutorials etc. and create high quality products that are well crafted, unique and fits what the market wants. This is essential for building a positive reputation and attracting customers.

- Determine what types of products that you want to make and sell, and research the market to understand your customers demand and potential base for those products.

- Set up a workspace where you can work on your lathe and create your products in your home or office. This should be a well ventilated area with good lighting and a big workbench that fits your needs.

- Purchase the materials and tools that you will need, such as metal stock, cutting tools, and any other necessary supplies.

- Create a website or online presence like a Instagram where you can showcase your products and accept orders from customers. This could involve setting up an online store on a marketplace platform, or creating your own website.

- Start marketing your products and make a variaty of different products to showcase your customers.. When you have your products you could reach out to potential customers, participating in trade shows and events, and using social media to promote your business and get sales.

- Set prices for your products and services so it fits the market and gives a little cash left after all expenses, remember to taking into account the cost of materials, labor, and overhead expenses.

- Deliver high quality products and excellent customer service to build a positive reputation to get more sales and customers that are coming back.

- Continuously improve and expand your product offerings to stay competitive and meet the evolving needs of your customers.

Is Buying a Metal Lathe Worth it?

Whether or not buying a metal lathe is worth it will depend on your specific situation and needs but for making money it certanly is a great tool. But there are always a few factors to consider when you are deciding on buying a metal lathe.

The Cost

Metal lathes are really expensive, especially high-quality models if you decide to buy one of those right of the bat, but if you only plan to use it more occasionally or for simple tasks, it may not be worth the investment. But if you plan to use your machine regularly and for more complex projects, it certanly is worth the cost because you can make more advanced projects = more money.

Your Skills and Experience

If you are a skilled machinist or metalworker, you will likely be able to get more value out of a metal lathe then a regular person, but even if you are new to working with metal, you may want to start with a simpler and less expensive tool, such as a wood lathe, to develop your skills before investing in a metal lathe.

Projects You Want To Do

A metal lathe is a versatile tool that can be used for a wide range of projects, from making custom jewelry to creating sculptures to producing custom car parts. If you have specific projects in mind that require a metal lathe, it may be worth the investment. If you are not sure what you want to do with a lathe, it may be better to explore other options.

Buying a metal lathe can be a worthwhile investment for skilled machinists and metalworkers who have specific projects in mind and are willing to put in the time and effort to learn how to use the tool effectively.

Metal Lathe vs Wooden Lathe: What’s The Difference?

A metal lathe and a wooden lathe are both machine tools that are used to shape and finish materials. However, there are some key differences between the two types of lathes:

- Material – The most obvious difference is the type of material that each lathe is designed to work with such as wood and metal and that is why a it is used to shape and finish metal, such as steel, aluminum, and brass, while a wooden lathe is used to shape and finish wood.

- Cutting tools – Another difference is the type of cutting tools that are used on each lathe are typically used with high-speed cutting tools, such as lathe bits and drills, that are able to cut through metal quickly and efficiently. Wooden lathes, on the other hand, typically use chisels and other cutting tools that are designed to shape and finish wood.

- Precision and Speed – Metal lathes are generally more precise and faster than wooden lathes, due to its nature of the materials they work with and all cutting tools they use. Metal is a harder and more rigid material than wood, and it can be machined to a higher degree of precision. In addition, metal lathes typically have higher speed capabilities than wooden lathes, allowing for faster and more efficient cutting.

- Applications – Metal lathes and wooden lathes are used for different applications as we talked about earlier in the text, that is why metal lathes are typically used in industries such as automotive, aerospace, and medical device manufacturing, where precision and speed are important. Wooden lathes, on the other hand, are more commonly used for projects such as furniture making and woodturning, where the focus is on shaping and finishing wood.

I would say that most metal lathes and wooden lathes are similar in most ways, but they have some important differences, such as the materials they work with, different cutting tools they use, precision and speed they offer. Choosing the right type of lathe will depend on different project and application you plan to work with.

Are There Alternatives to Metal Lathes?

There are many cool alternatives to metal lathes that include wood lathes, ceramic and glass lathes, and multi-purpose lathes that are capable of working on many different types of materials. But there is also computer numerical control (CNC) lathes that use a computer to control the cutting tools.

List of different alternatives to metal lathes.

- 1. Wood Lathes

- 2. Mini Lathes

- 3. Multi-Purpose Lathes

- 4. Milling Machines

- 5. Router Motors

- 6. Drill Presses

- 7. Bandsaws

- 8. Hot Wire Cutters

- 9. CNC Machines

- 10. Shaper Cutters

- 11. Hand Sanders

- 12. Grinding Wheel

- 13. File System

Frequently Asked Questions (FAQs)

Is a Metal Lathe a Good Investment?

Yes, a metal lathe can be a great investment. Metal lathes are extremely versatile tools, and they can be used to create loads of different things.

What Can I Make and Sell With a Metal Lathe?

Customized tools, engraved ornaments, customized jewelry pieces (rings, earrings, pendants, etc.), metal sculpture, miniature statues, customized bicycle parts, detailed picture frames, customized musical instruments,customized fishing tackle components and much more.

Can You Make a Living With a Metal Lathe?

Yes, it is possible to make a living using a metal lathe. With the right skills and experience, a metalworker can use a lathe to make machine parts.

Can You Make Money With a Metal Lathe?

Yes, you can make money using a metal lathe. Metalworking businesses and hobbyists alike can use the lathe to create items for sale or use in other

Conclusion

By learning how to make money with a metal lathe you develop a business specializing in providing machining services such as turning or milling services. It is important to create relationships with businesses that need machining services and offer competitive pricing.

Marketing your services the right way and expanding your customer base should be a priority in this kind of way of making money and that is because you are not making products that people throw away after one use, you make quality products that will last for a long time. So with the right attitude, dedication, and commitment to quality, a metal lathe can be a great way to start your first side hustle and generate extra money.

Related: